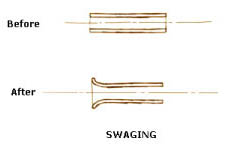

Swaging is a process that is used to reduce or increase the diameter of tubes. The inner diameter can be a different shape, for example a hexagon, and the outer is still circular.

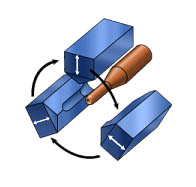

Pittsburgh Tubular Shafting has developed extensive data relative to the rotary forging of journals integral to the tube, used as the roll body. Micrographic analysis and destructive testing have validated strength increases in the forged end section resulting in dramatic grain refinement of the steel structure affording greater toughness characteristics typical of the forging process. X-ray defraction analysis records no residual stresses for the PTS process which aids holding close tolerances during the further processing of PTS rolls. Complete metallurgical data regarding the integrity of the process and product is available on request.